Glass Reinforced Plastic (GRP), often referred to as fiberglass, is a composite material made from plastic reinforced with fine glass fibers. The result is a strong, durable, and versatile material that is used in a wide range of industries, from construction and automotive to aerospace and marine applications. GRP combines the benefits of plastic, such as resistance to corrosion and flexibility, with the strength and durability of glass fibers.

Composition of GRP

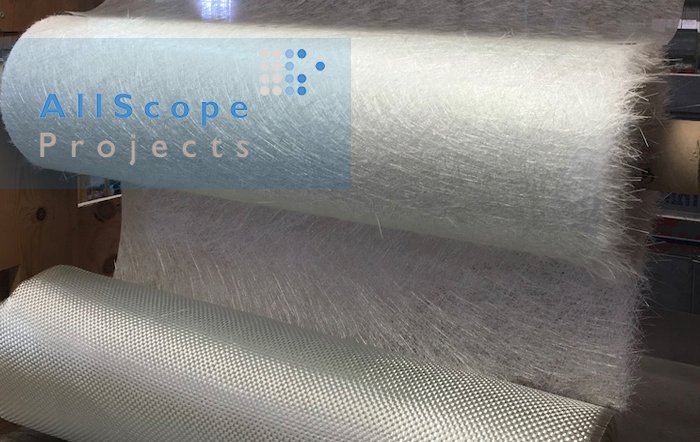

GRP consists of two main components:

- Polymer Matrix: This is the base material, usually a thermoset plastic such as polyester, epoxy, or vinyl ester resin. The resin serves as the binder, holding the glass fibers in place and providing the material with its basic structural integrity.

- Glass Fibers: These are fine strands of glass, which are woven or chopped into mats or rovings. The glass fibers provide the reinforcement that gives GRP its strength, rigidity, and impact resistance.

The combination of these two materials creates a composite that exhibits the best qualities of both components—lightweight yet strong, flexible yet durable. The ratio of resin to glass fibers varies depending on the specific requirements of the application, but typically, the fiber content ranges from 30 to 70 percent.

Manufacturing Process

The process of manufacturing GRP typically involves one of the following techniques:

- Hand Lay-Up: In this traditional method, layers of glass mat or woven rovings are manually placed into a mold. Resin is then applied and worked into the fibers using brushes or rollers. This method is labor-intensive but offers flexibility in producing custom shapes and sizes.

- Spray-Up: This method is similar to hand lay-up but uses a spray gun to apply the resin and glass fibers simultaneously. This process is faster than hand lay-up and is often used for larger production runs of parts with less complex geometries.

- Resin Transfer Molding (RTM): RTM involves placing dry glass fibers into a mold and then injecting liquid resin under pressure. This process allows for higher fiber content and better quality control.

- Pultrusion: Pultrusion is a continuous process where fibers are pulled through a resin bath and then through a heated die to form rigid profiles. This process is typically used for producing consistent cross-sectional shapes, such as beams, rods, and channels.

Each of these methods can result in a different final product, allowing manufacturers to tailor GRP to meet the specific needs of a given application.

Properties of GRP

GRP exhibits a range of properties that make it suitable for a wide variety of applications:

- High Strength-to-Weight Ratio: One of the most notable features of GRP is its high strength-to-weight ratio. The glass fibers contribute strength and rigidity while the resin keeps the material lightweight. This makes GRP an ideal material for industries where weight reduction is important, such as in automotive or aerospace.

- Corrosion Resistance: Unlike metals, which can corrode when exposed to moisture or chemicals, GRP is highly resistant to corrosion. This makes it a popular choice for applications in environments where exposure to water or chemicals is a concern, such as marine vessels or chemical tanks.

- Electrical Insulation: GRP has excellent electrical insulating properties, making it suitable for electrical and electronic applications.

- Flexibility in Design: GRP can be molded into complex shapes, providing flexibility in design. This ability to create intricate shapes and forms is one reason why GRP is used in many industries, from automotive body panels to architectural features.

- Thermal Insulation: GRP is a poor conductor of heat, which makes it useful for applications requiring thermal insulation.

- Durability: GRP is resistant to many environmental factors, such as UV radiation, temperature extremes, and chemicals. It is also resistant to fatigue, meaning it can withstand repeated stress without failing.

- Low Maintenance: GRP does not require much maintenance, as it does not rust, corrode, or degrade easily. It can be cleaned with regular washing and does not need painting or sealing as often as metals.

Applications of GRP

The versatility of GRP means it finds use in many different fields. Some of the major applications include:

- Construction and Architecture: GRP is often used in the construction of prefabricated buildings, roofing systems, and cladding. Its corrosion resistance and ability to be molded into different shapes make it ideal for architectural elements, such as decorative facades, domes, and spires.

- Marine: In the marine industry, GRP is used to build boats, yachts, and other watercraft. Its corrosion resistance and lightweight properties make it the material of choice for boats that need to withstand constant exposure to water and salt.

- Automotive: GRP is used in the automotive industry for parts such as body panels, bumpers, and dashboards. The material’s lightweight and durable properties contribute to fuel efficiency and safety in vehicles.

- Aerospace: In aerospace, GRP is used for the construction of components like wings, fuselage parts, and interior panels. The material’s strength-to-weight ratio is a key advantage in this industry, where minimizing weight while maintaining structural integrity is crucial.

- Electrical and Electronics: Due to its insulating properties, GRP is used in electrical enclosures, circuit boards, and other components that require electrical insulation.

- Sports Equipment: GRP is used in the manufacturing of sports equipment such as tennis rackets, fishing rods, and bicycles. The material’s strength, lightweight nature, and ability to be molded into precise shapes make it ideal for sporting goods.

Conclusion

Glass Reinforced Plastic (GRP) is a versatile and durable composite material with a wide range of applications across many industries. Its combination of strength, lightweight, corrosion resistance, and design flexibility makes it an essential material in construction, automotive, aerospace, marine, and many other sectors. As technology advances and new manufacturing techniques are developed, the use of GRP is expected to continue growing, further solidifying its position as a key material in modern engineering and design.